Excellence in Stainless Steels

Aamor Inox is a globally recognized leader in the manufacturing and export of high-quality Specialty Steel Long products in Stainless steels, known for its consistent quality, high-machinability, precision and customer-centric approach.

With over 25+ years of experience in the stainless steel industry, we proudly serve clients across 60+ countries, delivering products for critical applications across Automotive, Oil & Gas, Chemical & Petrochemical, Food & Dairy, Nuclear & Aerospace industries

years of experiencein the stainless steel industry

tons of stainless steel every year

countries around the globe

customers

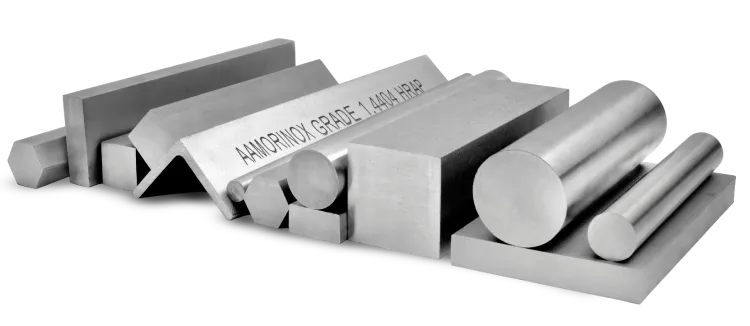

Aamor Inox has carved its niche into PSQ / BSQ / Shafting bars in grades like 416, 410, 17-4ph, 316L, 304N, 1.4462 (F51), 1.4104, 1.4057 (431), 1.4021 (420), 1.4028 (420B), 1.4034 (420C) etc, in stricter size tolerances like f6, h6, k6, j6, e6, g6, g7, h7, f7, e8, h8, f8 or +0.000/-0.0005” in surface-finish of Ra 0.2 um (12 RMS) and Straightness 0.25mm/meter (0.0010" per foot T.I.R).

Being India’s largest producer of these high-precision bars, Aamor Inox can supply special-long-length precision bars in lengths up to 11.50 meters (37 feet long), allowing us to meet very specific customer requests for nonstandard PSQ requirements on an expedited basis.

Aamor Inox PSQ / Shafting Bars are more than 8 times straighter than industry standards (ASTM A108), with straightness readings of 0.0015” T.I.R per ft max.

Global Leaders. Real Testimonials. Proven Excellence.

At Aamor Inox, we do more than supply stainless steel bars—we build lasting partnerships. Here’s what our partners say about our quality, service, and commitment. Trusted by Industry Leaders. Recognized Worldwide.

India’s first stainless steel mill with a NADCAP-accredited heat treatment facility — the benchmark for Aerospace and Defense manufacturing. Click here: why Aerospace & Defence Trust Us

At Aamor Inox, quality isn’t just a goal—it’s the foundation of everything we do.

Our latest state-of-the-art NDT (Non-Destructive Testing) setup features fully-automated Ultrasonic Testing with Water Immersion technology and advanced Eddy Current testing systems equipped with Circograph and Defectomat units from Dr. Foerster, Germany—ensuring stainless steel bars that are completely free from defects.

In addition to the stringent process control techniques followed during production, Aamor Inox carry out comprehensive Chemical, Mechanical & Metallurgical testing on the final products – ensuring strict adherence to customer specifications and performance expectations.

High-Machinability

High-Machinability

We very well understand that a great machinability isn’t just an advantage—it’s a necessity. Most of Stainless-steel bars undergo rigorous machining processes, and that’s why we’ve spent over 20 years refining our process to deliver stainless steel bars that machine faster, last longer, and perform better.

We pay special attention to diameter tolerances, mechanical properties, roundness, and straightness, ensuring our bars meet the highest demands of high-tech machine shops running multi-spindle machines like the INDEX MS40.

At Aamor Inox, machinability isn’t just a feature. It’s our passion.

View Our Product RangeGreat Place to Work

Great Place to Work

At Aamor Inox, this belief isn’t just a statement, t’s our way of life. Being certified as a Great Place to Work for 2025–2026 (3rd time in a row) is a true testament to the thriving culture we've nurtured- one rooted in excellence, innovation, and collaboration. This recognition reflects our unwavering commitment to creating not just a workplace, but a community where people grow, lead, and succeed—together.

Focused on fostering leadership, continuous learning, and a culture of safety, we are not just shaping stainless steel, we’re shaping futures.