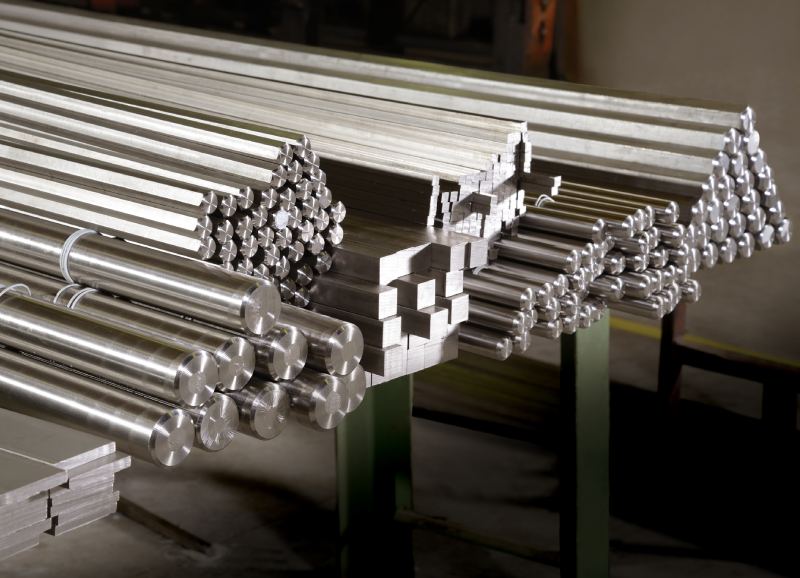

At Aamor Inox, we don’t just manufacture stainless steel bars — we engineer performance. Every grade we produce is carefully chemically designed to deliver the perfect balance of strength, corrosion resistance, machinability, and consistency for your specific application.

Whether you’re in automotive, aerospace, marine, defense, oil & gas, food processing, medical, or general engineering, we have the metallurgical expertise and manufacturing capability to deliver world-class stainless steel grades in Round Bars, Squares, Hexagons, Angles and Flats.

Aamor Inox – Our Core Strengths in Specialty Grades

At Aamor Inox, we know that many industries demand more than standard stainless steel — they require alloys precisely engineered to excel under extreme conditions, deliver exceptional mechanical performance, and ensure absolute reliability in mission-critical applications.

With over two decades of expertise, we’ve perfected select stainless steel grades that consistently surpass industry benchmarks—offering superior mechanical strength, exceptional wear and corrosion resistance across varied environments, and machinability that outperforms the norm.

These Grades are:

These grades are available in multiple conditions — annealed, hardened, or precipitation-hardened — to meet exact application requirements.

For detailed specifications, sizes, and mechanical properties, you can access our comprehensive catalogs here:

Besides above, we manufacture a comprehensive range of stainless steel grades to meet the toughest demands across industries. Every grade is produced with tight chemical control, dimensional precision, and full traceability, in compliance with ASTM, EN, and DIN standards.

Renowned for their exceptional corrosion resistance, toughness, and formability. Ideal for applications demanding hygiene, strength, and a long service life

Chosen for their hardness, wear resistance, and ability to be heat-treated. Perfect for precision tools and high-strength components.

A cost-effective choice for moderate corrosion resistance with excellent thermal conductivity.

Combining the best of austenitic and ferritic properties for outstanding strength and chloride stress corrosion cracking resistance.

Delivering high strength , good corrosion resistance, and excellent machinability after aging.

Designed for superior performance at elevated temperatures and in aggressive environments.

Every Aamor Inox bar is produced in our fully automated, state-of-the-art mill, backed by stringent in-line and laboratory testing to ensure mechanical, chemical, and dimensional accuracy. Our Quality Management System and process certifications stand as proof of our unwavering commitment to global manufacturing standards.

At Aamor Inox, we understand that every application demands precision — not just in dimensions, but in chemistry, strength, and machinability.

Our technical sales team is just a message away. Get detailed chemical composition sheets, mechanical property charts, and machining guidelines — all tailored to your specific application.