At Aamor Inox, precision is not just a process — it’s our promise.

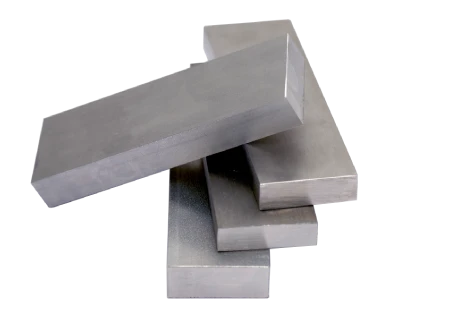

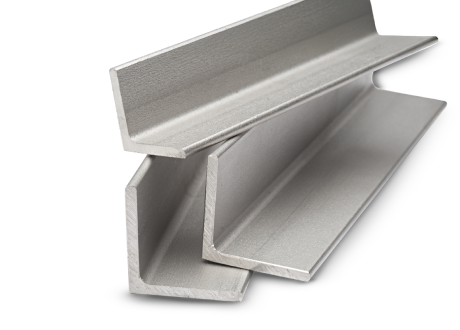

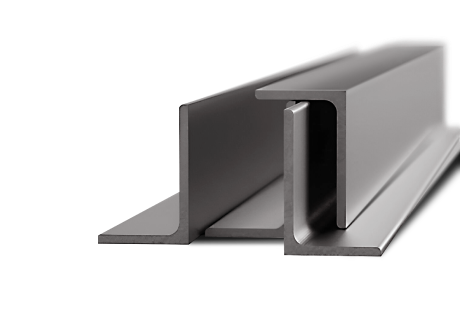

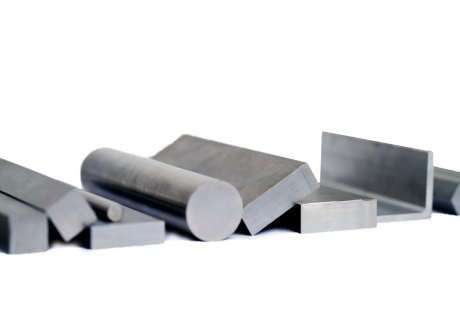

We manufacture and supply world-class stainless steel bars and specialty alloys for the most demanding industries — from aerospace and automotive to oil & gas and medical applications — where performance, safety, and reliability are simply non-negotiable.

We deliver more than just stainless steel — we deliver precision, performance, and trust.

At Aamor Inox, machinability isn’t a bonus — it’s a necessity.

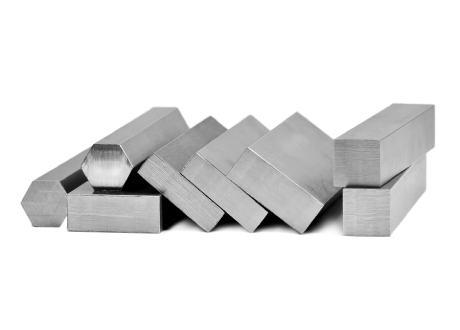

With over 20 years of refinement, our stainless steel Round Bars & CD Hexagons are engineered to machine faster, last longer, and perform better. We maintain tight tolerances, perfect roundness, and superior straightness to meet the demands of high-tech multi-spindle machines like the INDEX MS40.

Plus, our fully automated double-side chamfering line provides precise, customized chamfering (30º, 45º, 60º) with 2-5mm chamfer lengths, making bar feeding even more seamless.

We ensure that every bar you receive performs flawlessly on the shop floor.

Our customers report up to 20% better machinability than industry standards—meaning faster production, lower costs, and higher efficiency.

Among the most demanding machining shops worldwide, our bright bars are the gold standard. Count on Aamor Inox as your trusted source for bright round bars from India.

Contact our technical sales team today for complete specifications, grades, and customization options. Contact Us

Value-Added Processing — Beyond Supplying Bars, We Deliver Ready-to-Use Solutions

At Aamor Inox, we go beyond manufacturing — delivering stainless steel bars ready for your success.

Our Promise: Every product, every time — right quality, right properties, right on time.

Your Reliable Partner in Stainless Steel Excellence

With a reputation built on quality, consistency, and trust, Aamor Inox stands as the preferred partner for clients worldwide. Whatever your industry or application, we ensure our products perform flawlessly — so you can deliver with confidence.

At Aamor Inox, we don’t just sell bars — we deliver the foundation for your engineering excellence.

Let’s discuss your next project or stock replenishment needs. Contact us for detailed specifications, grade recommendations, and a tailored quotation today.