At Aamor Inox, quality is not a department — it’s a way of life. Every stainless steel bar we manufacture carries our legacy of precision, integrity, and performance. For over two decades, we’ve built our reputation by holding ourselves to the highest standards — because when our customers rely on us, we leave no room for compromise.

Our commitment to delivering ultra-high-precision stainless steel bars begins with a quality-first mindset and is reinforced through advanced systems, skilled professionals, and a culture of continuous improvement.

At Aamor, quality isn’t confined to the QA department. From production to packaging, every team member is trained, empowered, and aligned to uphold our promise of excellence.

Our stainless bars are trusted in industries where failure is not an option — aerospace, automotive, medical, oil & gas, and high-precision machining.

Whether it’s DIN, ASTM, EN, or JIS standards — we meet or exceed them all. And for clients requiring extra-low inclusion levels, custom mechanical properties, or clean-room packaging — we’ve got that covered too.

Request sample Mill Test CertificateWe believe that quality begins before production — with the right mindset, systems, and materials.

From metallurgical planning to the final packaging, every stage is engineered to uphold:

Our facilities meet — and often exceed — the most stringent global standards, ensuring unmatched product performance, reliability, and compliance across critical industries –

At Aamor Inox, quality isn’t just a department — it’s the foundation of everything we do. With a legacy of consistency and precision, our stainless steel bars have stood the test of time across industries and continents.

We are proactive in our pursuit of excellence, combining innovation, technical rigor, and customer-centricity to deliver high-quality stainless steel bars — at competitive prices and with timely, dependable service.

Crack Detection & Surface Integrity Testing

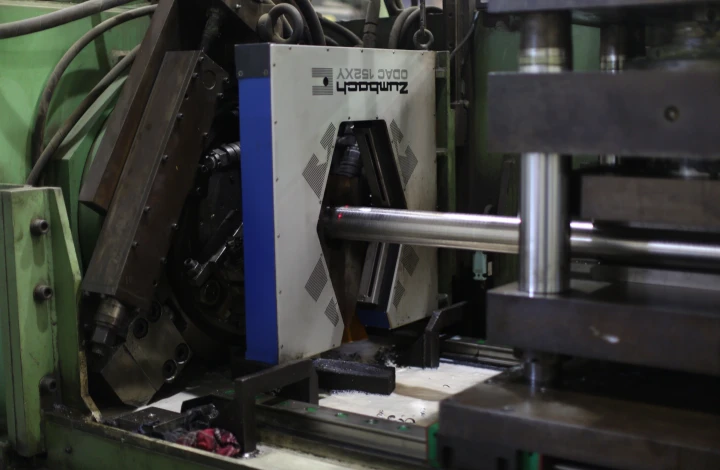

Fully Automatic Eddy Current Testing (Circograph)

Fully Automatic Ultrasonic Testing Machines

Magnetic Particle Inspection (MPI)

Mechanical Testing

Metallurgical Testing

Other Specialized Tests

With a rejection rate of less than 0.50% and customer satisfaction scores among the highest in the industry, Aamor Inox doesn’t just meet expectations — we set new benchmarks in quality.

We understand the cost of a quality failure — lost production time, client dissatisfaction, and brand damage. That’s why at Aamor, we promise:

When you choose Aamor Inox, you’re not just buying a product — you’re investing in predictability, partnership, and peace of mind. That’s the power of precision-driven quality.

The consistency of Aamor’s quality, even across large volumes, is what sets them apart. We trust their bars in our most demanding applications.

— Global Automotive Customer