We’re proud to be India’s most advanced manufacturer of stainless steel long-products.

Whether you’re an OEM needing precision stainless steel bars, or a buyer looking for small-lot flexibility, our scale never comes at the cost of customization. With a capacity of over 50,000 tons/year, we deliver more than 150+ steel grades in custom sizes, finishes, and tolerances — all backed by industry-leading turnaround times.

Operating out of two state-of-the-art production sites spanning 18 acres (75,000 sqm), just 50 mins drive from Delhi International Airport, we combine global technology with deep metallurgical expertise. From hot rolling to ultra-precision cold finishing, every process is built for excellence.

Request a Plant VisitWhat Sets Us Apart

We’re always investing to improve productivity — but never at the cost of quality.

Anand GuptaFounder & CEO

No other competitor matches our depth of expertise in manufacturing ultra-high-precision stainless steel bars.

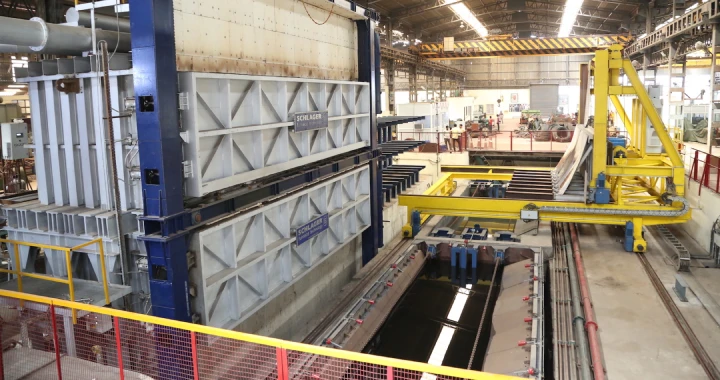

Here is a sneak peek into our manufacturing capability –

Our ultra-modern heat treatment furnaces are supplied by Schlager Industrieofenbau GmbH (Germany). Both furnaces are equipped with data logging and temperature uniformity features. We meet NORSOK, AMS 2750E, and API-6A norms. Our facility is NADCAP accredited — a global standard for Aerospace and Defence.

Heat Treatments available with Aamor Inox are –

The Oil & Water Quenching tanks are equipped with a very strong agitation mechanism which assures controlled cooling curves during Quenching process. This makes Aamor Inox a leader for all heat-treated Stainless steels like 410, 416, 420, 430F, 431, Duplex F51, 17-4ph, 1.4418, 310S etc

Among India’s most advanced bar finishing lines — fully automated, fully integrated, and built for precision. Equipped with a very advanced high-precision cutter heads for achieving desired roundness, ovality and lobing in bars. Equipped with advanced Laser size measurement system from Zumbach.

Latest generation, fully-automatic grinders from Landgraf & MAIR (Italy) for exceptional precision and straightness.

These grinding lines allow us to supply highly rounded bright bars with special ovality and out-of-roundness. These bars are available in h9, as well as in special tolerances like h6, e6, f7, h7, h8, f8 etc.

Precision straightening machines and chamfering lines that allow us to cater to custom lengths and tolerances for demanding downstream applications.

With two world-class facilities located in Ghaziabad (Uttar Pradesh), just less than 60 minutes from Delhi International Airport, and well connected to India’s major sea ports, our facilities are designed for global accessibility and logistical efficiency. But beyond location, it’s the depth of our capabilities, the precision of our processes, and the integrity of our execution that truly sets us apart.

Our flagship site dedicated to Round-bars finishing excellence including our NADCAP-accredited heat-treating furnaces. Here, we hot-roll, heat-treat and cold finish (peeling, drawing, grinding, chamfering, polishing etc) and inspect bars for dimensions through the lasers and finally crack-test via fully automatic Eddy Current & fully automatic UT testing machines. This unit also houses fully automatic centerless grinding lines from MAIR and Landgraf (Italy), precision straighteners, and advanced testing systems.

Browse Our Photo GalleryExplore Our Product CapabilitiesOur newest plant: home to our new in-house rolling mill and end-to-end machinery for cold-finishing of all profiles and sections like Angles, Flats, Squares, Hexagons and even Round bars. This unit was recently started and has now become the hub for all our expansions.

Our latest SAP S4 HANA ERP system, combined with very efficient B.I. (Business Intelligence) MIS systems gives us a better control over our manufacturing processes at various stages and allows us to control the materials / orders throughout the supply chain in a much more effective manner.

SAP links both our production sites thereby guaranteeing rapid exchange of information and ensuring smart manufacturing workflows. This helps our team offer our customers around the world real time updates, without any communication problems or loss of time.

SAP-driven traceability ensures full process transparency, from billet to dispatch.

Even with world-class automation, it’s our people who make the difference. Many of our senior operators and engineers have been with us for two decades or more, delivering support, service, and solutions that no machine can replicate.

Aamor Inox management, starting from the top, insists that quality is the number one consideration. “We are of course investing with the aim to improve productivity, but never compromise on quality. We want to make the best bar that we can. The most important aspect of our new machines is that they can produce cold-finished steel bar with more consistency in all of the attributes of quality and do it at a significantly higher speed. All our bars are 100% Ultrasonic Tested for internal defects. This helps our customers fully rely upon our materials, thus creating a great value for our customers and ensuring that their experience with AamorInox remains the best in the industry” adds Mr. Anand Gupta.

Anand GuptaFounder & CEO

Interested in seeing the action up close?

Whether you’re a customer, partner, or curious collaborator — we’d love to show you around and experience the Aamor Inox difference.

Contact Our Manufacturing Team